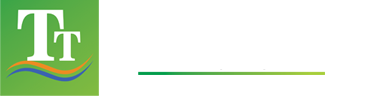

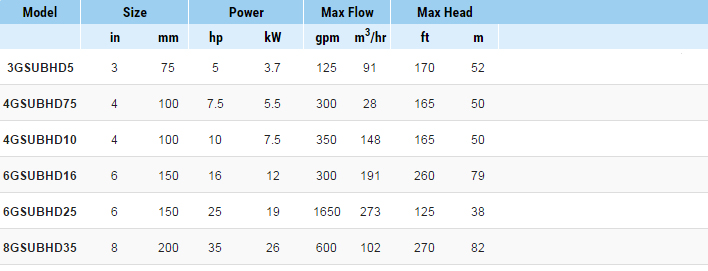

Global Pump portable electric submersible pumps are ideal for corrosive and abrasive applications. Ideal for low flow, high head applications. Available in models from 3″ to 8″ and 5 hp to 35 hp., these pumps can achieve max heads of 275 ft. and 1650 gpm.

CENTRIFUGAL WELLPOINT

Features

Stainless steel strainer, shaft, impeller, outlet and hardware for maximum corrosion resistance

Mechanical seals in wholly enclosed pressure compensated oil chamber

Nitride hardened 410 stainless steel impeller for abrasive applications

Tandem tungsten carbide/tungsten carbide and tungsten carbide/tungsten carbide mechanical seals

Field adjustable nitrile rubber-lined diffuser/ wearplate optimizes efficiency throughout the life of the pump

Equipped with sacrificial zinc anodes for maximum life in a saline fluid environment

Options

Choice of impeller materials including 304/316 stainless steel for sea water and corrosive applications

Available in complete 316 stainless steel construction with silicon carbide/silicon carbide mechanical seals and Viton elastomers

Automatic ON/OFF/ON thermal overloads embedded in stator winding (requires 6 core or control cable and external controls)

Global Pump portable electric submersible pumps are ideal for corrosive and abrasive applications. Ideal for low flow, high head applications. Available in models from 3″ to 8″ and 5 hp to 35 hp., these pumps can achieve max heads of 275 ft. and 1650 gpm.

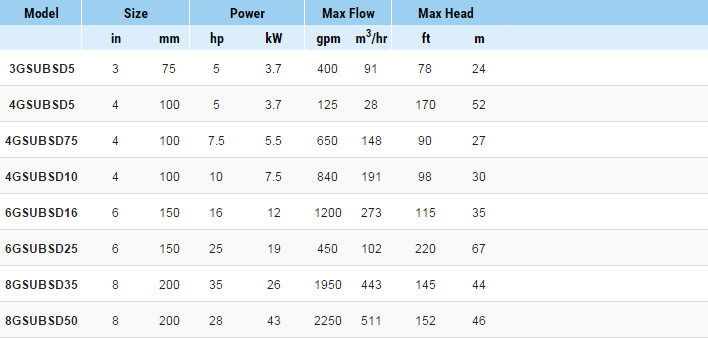

Global Pump® portable electric submersible pumps are ideal for corrosive and abrasive applications. Ideal for high flow,lower head applications. Available in models from 3″ to 8″ and 5 hp to 50 hp., these pumps can achieve max heads of 225 ft. and 2300 gpm.

CENTRIFUGAL WELLPOINT

Features

Stainless steel strainer, shaft, impeller, outlet and hardware for maximum corrosion resistance

Mechanical seals in wholly enclosed pressure compensated oil chamber

Nitride hardened 410 stainless steel impeller for abrasive applications

Tandem tungsten carbide/tungsten carbide and tungsten carbide/tungsten carbide mechanical seals

Field adjustable nitrile rubber-lined diffuser/ wearplate optimizes efficiency throughout the life of the pump

Equipped with sacrificial zinc anodes for maximum life in a saline fluid environment

Options

Choice of impeller materials including 304/316 stainless steel for sea water and corrosive applications

Available in complete 316 stainless steel construction with silicon carbide/silicon carbide mechanical seals and Viton elastomers

Automatic ON/OFF/ON thermal overloads embedded in stator winding (requires 6 core or control cable and external controls)

For more Global pump Products, Please visit Our Website at www.globalpump.com